Graphite felt electrode plays a crucial role in redox flow batteries, but despite its widespread use, certain limitations are associated with its performance, particularly in terms of mass transfer and reaction kinetics. Further research and work are essential to enhance the overall performance of redox flow batteries, making them more efficient, cost-effective, and suitable for a wider range of applications.

Chair Professor Tianshou Zhao and Associate Professor Lei Wei’s research group from the Department of Mechanical and Energy Engineering at the Southern University of Science and Technology (SUSTech) has recently reported a significant advancement in the development of high-performance electrodes for redox flow batteries.

Their work, entitled “Metal-free fabrication of nitrogen-doped vertical graphene on graphite felt electrodes with enhanced reaction kinetics and mass transport for high-performance redox flow batteries”, has been published in Advanced Energy Materials (AEM).

The electrode, crafted through a metal-free in-situ growth method, skillfully merges the benefits of a three-dimensional vertical structure with atomic doping. This innovation enhances mass transfer and reaction kinetics at the electrode/electrolyte interface, significantly improving key performance metrics like energy efficiency and power density of redox flow batteries.

The breakthrough deviates from traditional electrode design approaches and introduces a novel method to simultaneously enhance microscopic mass transfer and interfacial dynamics.

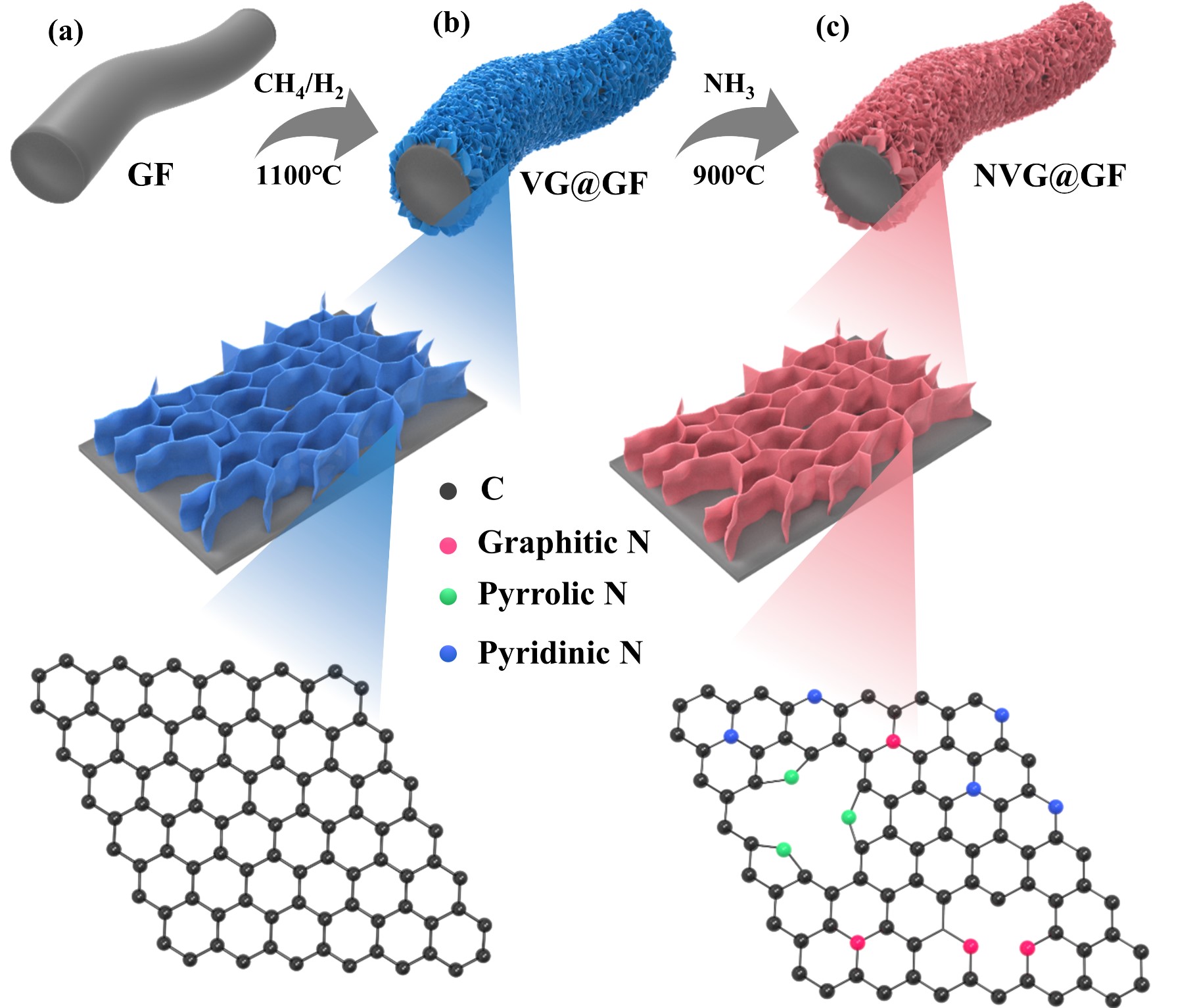

The study employed a thermochemical vapor deposition process to create a composite electrode (NVG@GF) consisting of a 3D vertical graphene structure and atomic doping (Figure 1), leading to synergistic enhancement of mass transfer characteristics and reaction kinetics.

Figure 1. Schematic diagram of the composite electrode manufacturing process

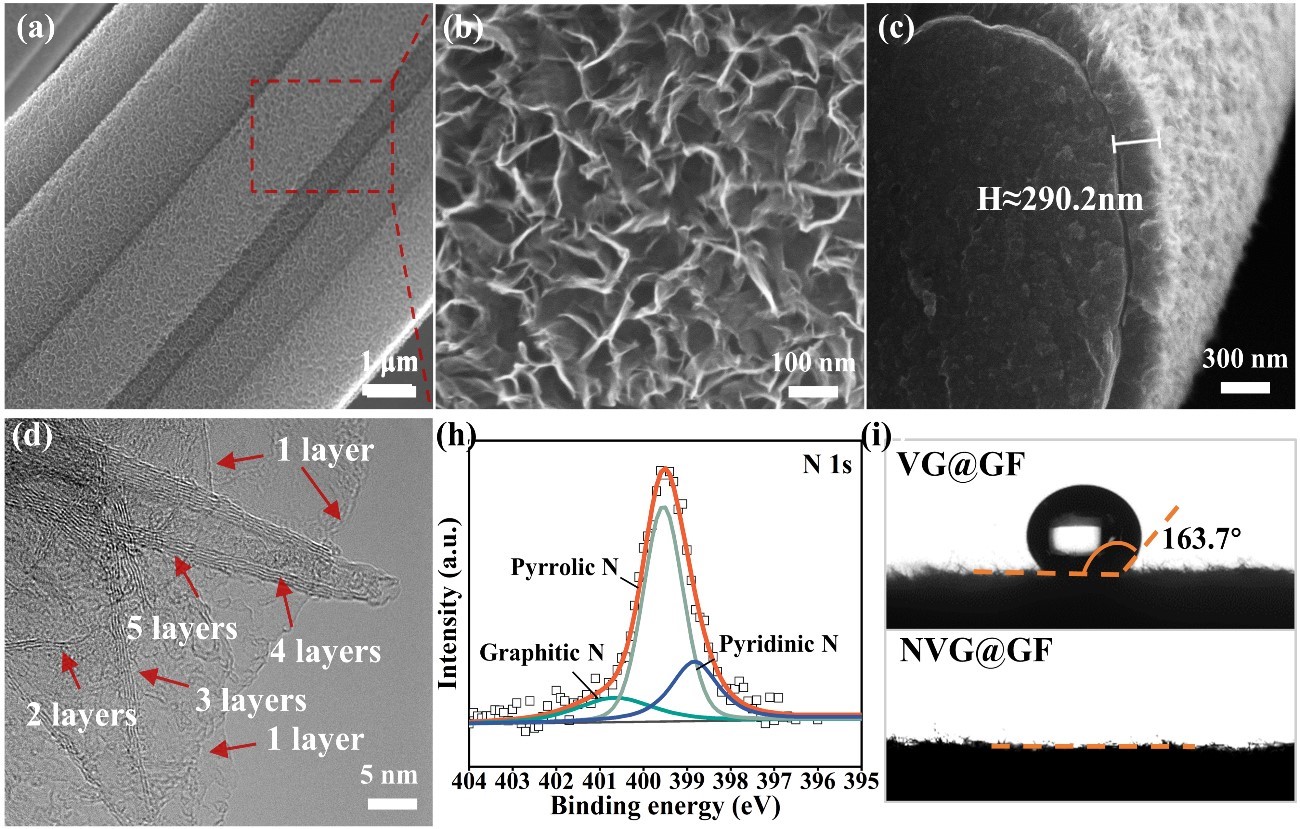

The researchers specifically explored the growth mechanism, microscopic structure, and composition of the composite electrode (Figure 2), revealing that the introduction of the vertical graphene structure and N-doping improved the microscale mass transfer of active substances in the original graphite felt, providing more interfaces for electrochemical reactions.

Figure 2. Characterization of the microstructure and composition of the composite electrode

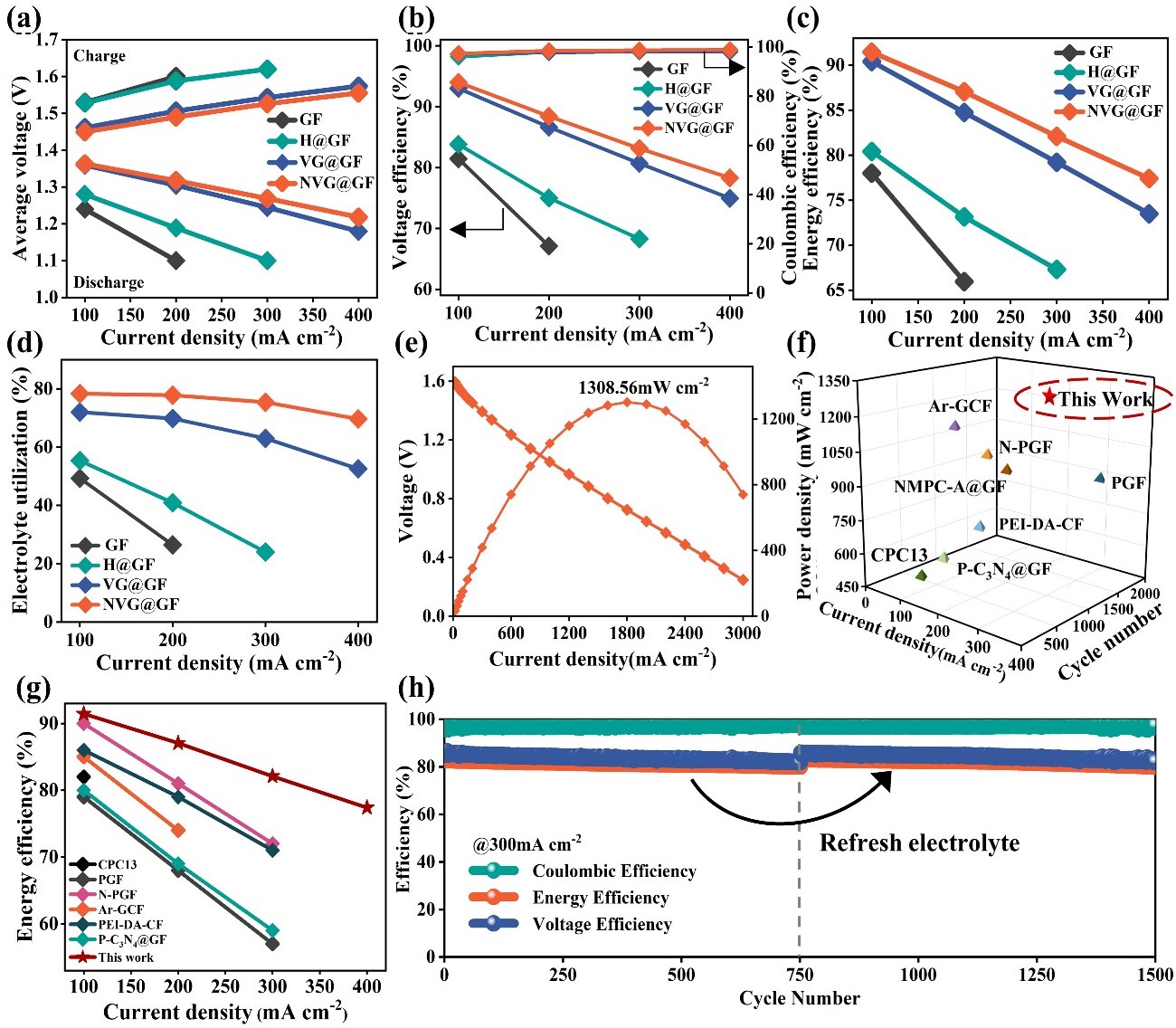

The electrochemical cyclic performance tests showed that the NVG@GF electrode maintained excellent performance even at high current densities, indicating great potential for real-world applications. Additionally, long-cycle battery testing revealed that after 1500 cycles, the energy efficiency of the NVG@GF electrode still exceeded 80.2%, confirming its remarkable stability.

Figure 3. Electrochemical performance test of composite electrode

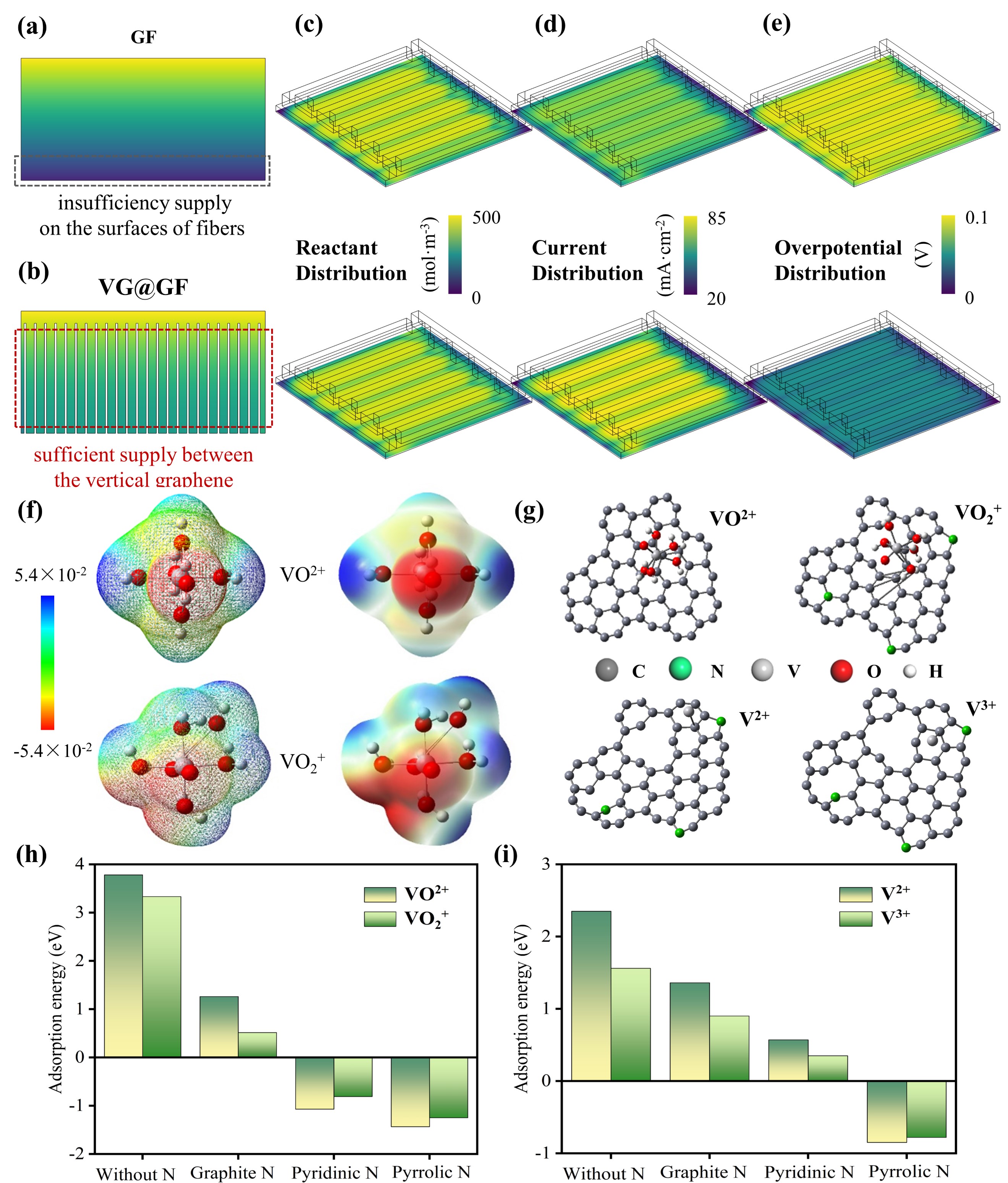

Furthermore, optimized operating conditions ensured highly uniform macroscopic mass transfer across the porous electrode, securing low local polarization and high power output. Density functional theory calculations further demonstrated the composite electrode’s design with strong ion adsorption properties, effectively enhancing reaction kinetics.

Figure 4. The multi-physics simulation and density functional theory results

In conclusion, the researchers developed a high-performance electrode using a metal-free method to grow nitrogen-doped vertical graphene in-situ. This technique synergizes vertical graphene’s structure with atomic doping to enhance flow batteries’ mass transfer and interfacial dynamics, significantly boosting their cycle life and power density, which is highly applicable to high-performance redox flow batteries.

Jincong Guo, a master’s student, and Lyuming Pan, a Ph.D. student, both of SUSTech, are the co-first authors of this paper. Chair Professor Tianshou Zhao, Associate Professor Lei Wei, and Researcher Meisheng Han are the corresponding authors. SUSTech is the sole affiliated institution of the paper.

This work was supported by the National Key R&D Program, National Natural Science Foundation of China (NSFC), Shenzhen Science and Technology Innovation Commission, and the China Salt Lake Industry Co.

Paper link: