The phenomenon of mass transfer dead zones within redox flow batteries has been discovered and reported, but its formation mechanism has not been systematically analyzed and discussed due to its involvement in multi-component, cross-scale, and multi-physical processes. The complex process of material transport and coupling reactions makes it difficult for the distribution of active species throughout the porous electrodes to be uniform everywhere.

Chair Professor Tianshou Zhao and Associate Professor Lei Wei’s research group from the Department of Mechanical and Energy Engineering at the Southern University of Science and Technology (SUSTech) has recently reported a general strategy for dead zone detection and compensation within redox flow batteries.

Their paper, entitled “Dead-zone-compensated design as general method of flow field optimization for redox flow batteries”, has been published in the Proceedings of the National Academy of Sciences (PNAS).

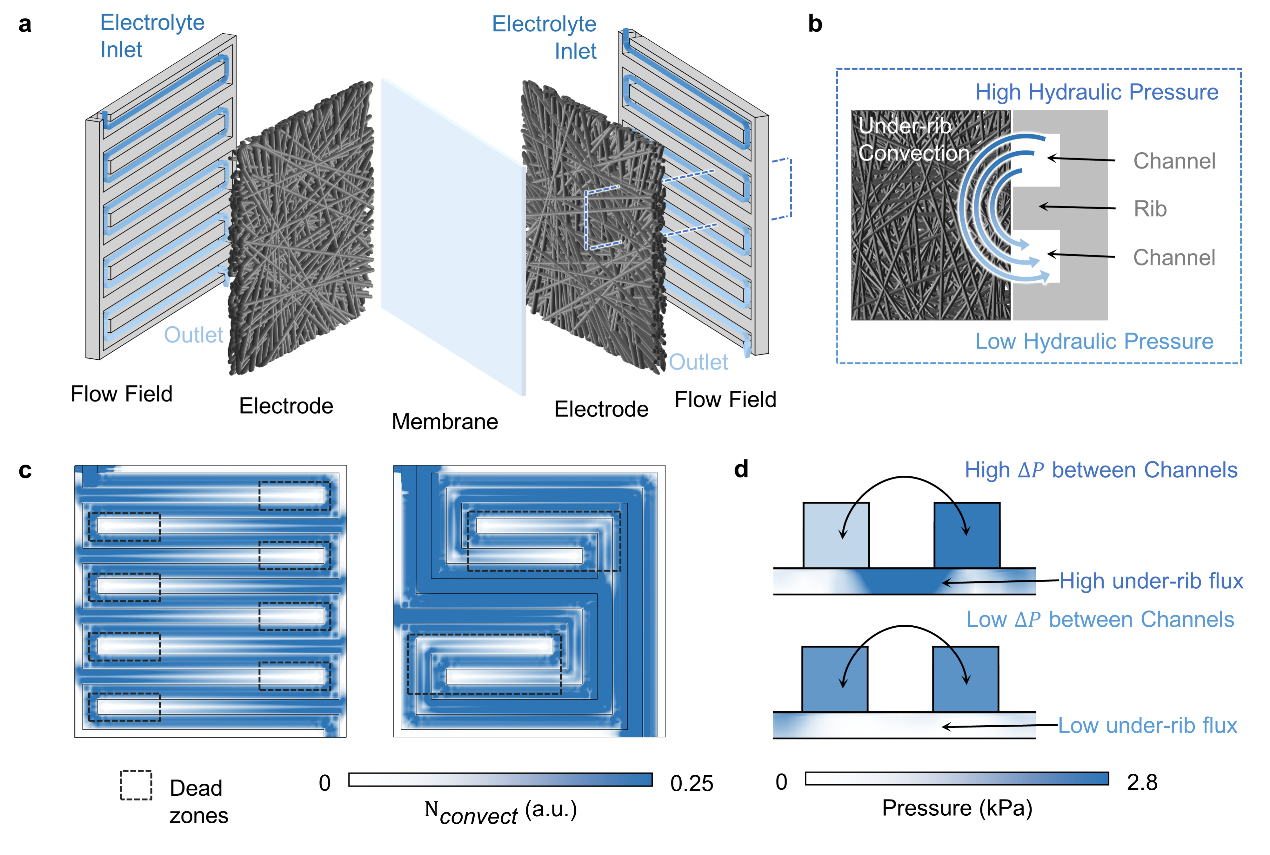

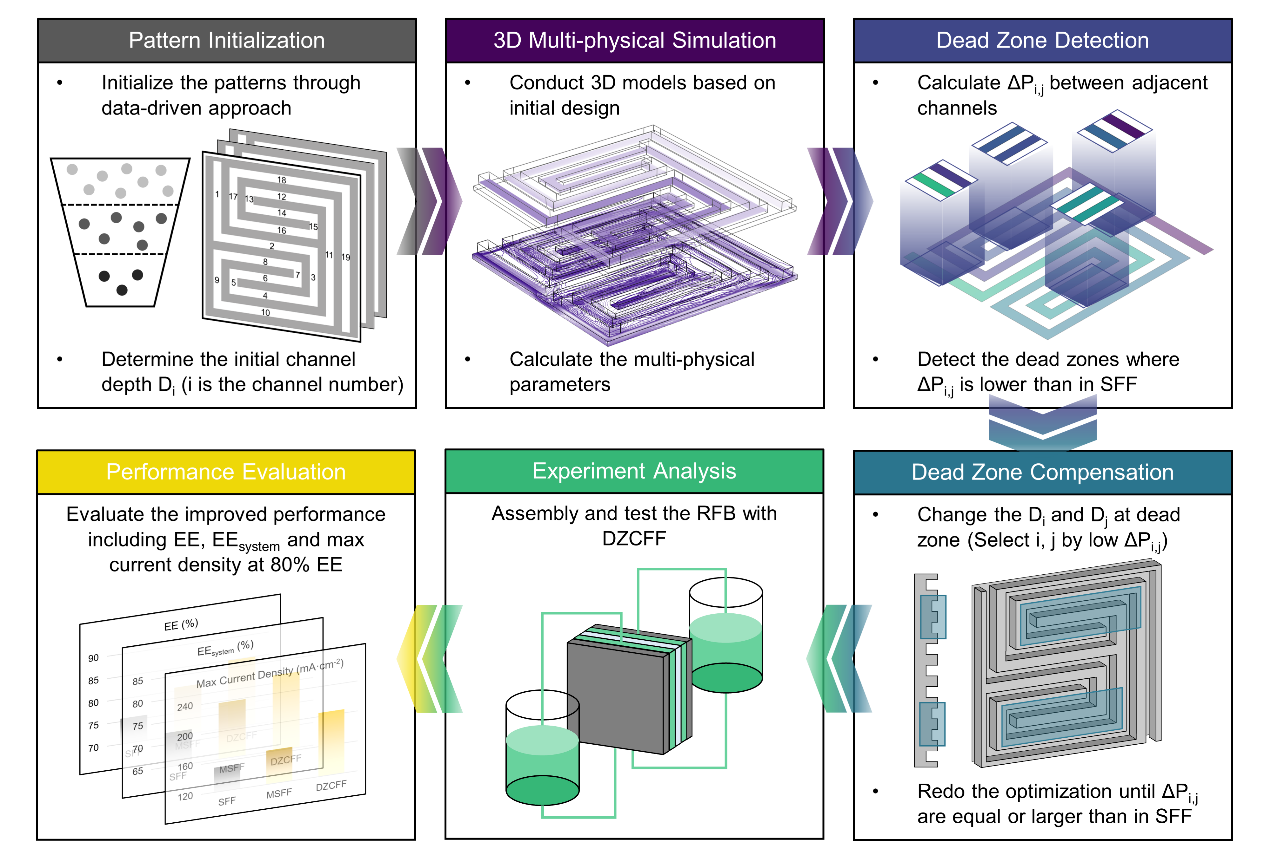

When using the convective flux of active species as an evaluation indicator, it is usually found that the mass transfer dead zone is strongly correlated with the design of the flow field pattern, the hydraulic pressure, and the under-rib convections (Figure 1). After clarifying the multi-component, multi-scale, and multi-physical field coupling processes involved in the formation of mass transfer dead zones, the researchers proposed a universal design method for the detection and regulation of redox flow batteries (Figure 2).

Figure 1. The formation mechanisms of mass transfer dead zones within redox flow battery

Figure 2. Workflow for dead zone detection and compensation based on existing flow fields

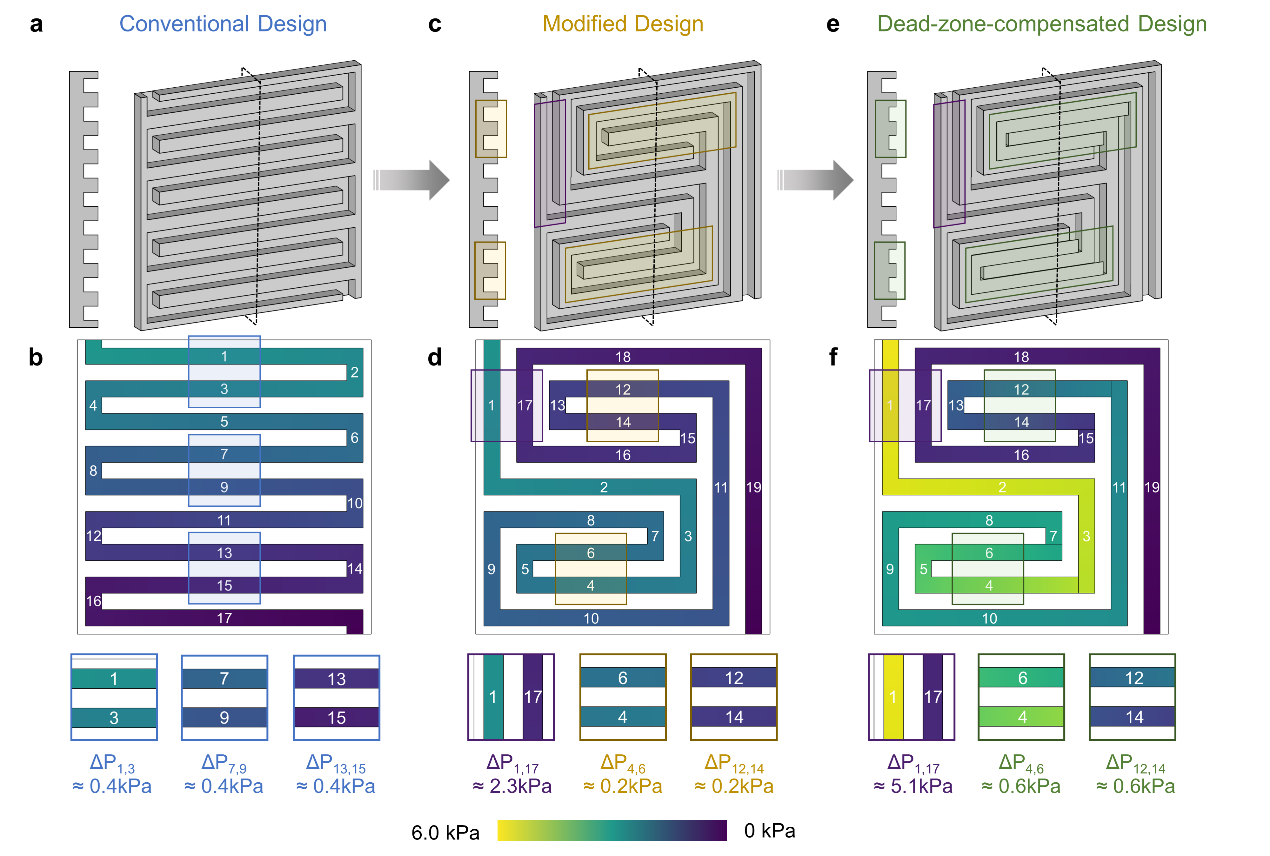

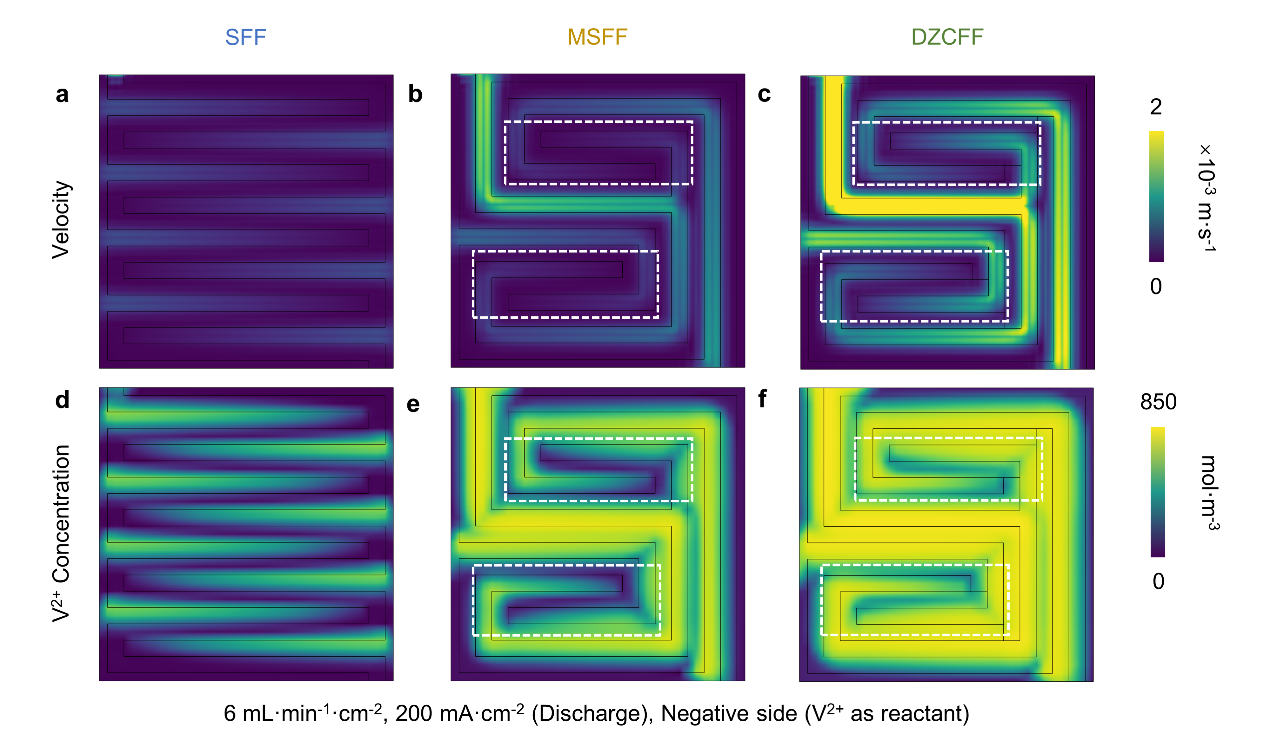

Based on the above methods, this study takes an all-vanadium flow battery as an example to build a 3D multi-physical numerical simulation model and experimental platform with vanadium ions as the active species, further verifying the detection and compensation effects. The 3D simulation results of both the conventional serpentine flow field and the modified serpentine flow field show low-pressure-difference areas. After iterative optimization, the novel design will significantly improve the pressure difference of adjacent channels (Figure 3). The 3D multi-physical field simulation results show that the electrolyte flow rate and reactant concentration in the corresponding region significantly increase (Figure 4).

Figure 3. Hydraulic pressure distribution in the flow channel before and after compensation

Figure 4. Distribution of electrolyte flow rate and reactant concentration before and after compensation

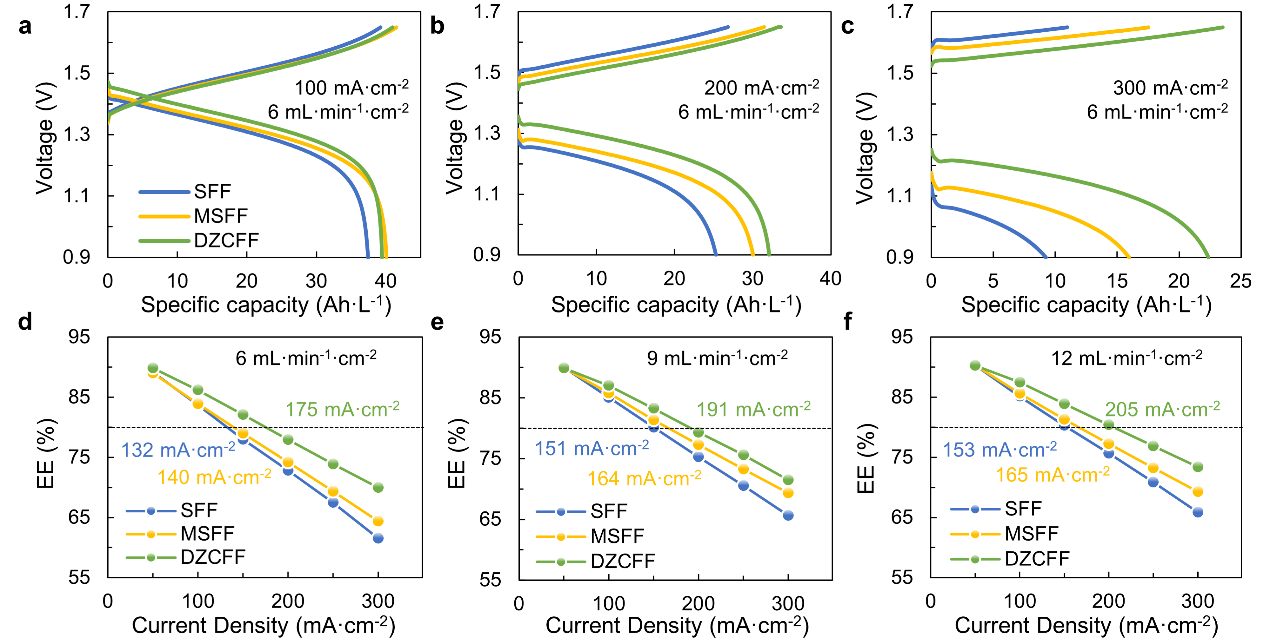

On this basis, the electrochemical performance of redox flow batteries can be quantitatively verified by comparing multiple key indicators. The improvement of the average concentration and distribution uniformity factor of active species in the porous electrode on the negative side during the discharge process is strong evidence for the compensation of the mass transfer dead zones (Figure 5). Meanwhile, the novel flow field increases the pressure drop to a certain extent, sacrificing a portion of the pump power. The charge-discharge and energy density curves compared the battery capacity retention rate and energy efficiency before and after compensation, and the maximum applied current density reached 205 mA cm-2 when ensuring an energy efficiency of 80% (Figure 6).

Figure 5. Numerical simulation of battery performance before and after compensation

Figure 6. Battery performance verified by experiments before and after compensation

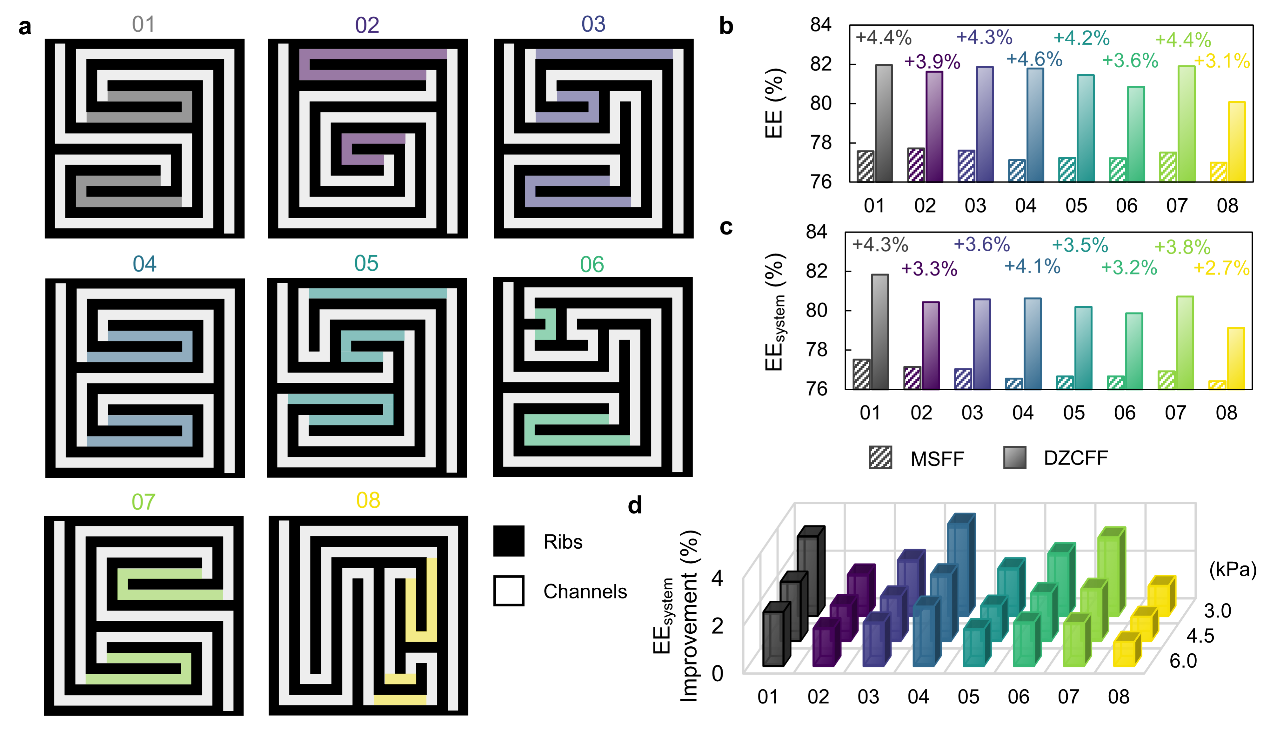

The above results fully validate the effectiveness of the proposed method from theoretical, simulation, and experimental aspects. In addition, this design method has universality and can be transferred and applied to other flow field patterns. Under the same electrolyte flow rate, using energy efficiency and pump loss corrected system energy efficiency as evaluation indicators, introducing dead-zone-compensation design can achieve improvements of 3.1~4.6% and 2.7~4.3%, respectively (Figure 7).

Figure 7. The generality of the proposed method applying to different flow field patterns

In conclusion, this work focuses on the phenomenon of mass transfer dead zones commonly present in redox flow batteries, revealing the causes and influencing mechanisms of flow field design and mass transfer dead zones. Starting from the coupling mechanism of multiple components, scales, and physical fields, a general method for detection and compensation is proposed. The combination of a 3D multi-physical numerical simulation model and experimental analysis has comprehensively verified the improvement effect of the proposed design on the performance of redox flow batteries, and has great potential for application in the design of large-scale redox flow battery stacks.

Lyuming Pan from SUSTech and Jing Sun from the Hong Kong University of Science & Technology (HKUST) are the co-first authors of this article. Profs. Tianshou Zhao and Lei Wei at SUSTech are the corresponding authors.

This work was supported by the National Key R&D Program of China, National Natural Science Foundation of China (NSFC), Shenzhen Key Laboratory of Advanced Energy Storage, and the Joint Research Center on Energy Storage Technology in Salt Caverns Program.

Paper link: